- Home

- About Us

- Products

&

Services

- Products

- Manual RO Water Treatment Plant

- Automatic RO Water Treatment Plant

- IoT enabled RO Water Treatment Plant

- Disinfection System for Municipal Water

- Deionization Water Treatment Plant (CDI)

- Custom-Engineered Water Treatment Systems

- Water Management Systems

- Water Conditioner and Softeners

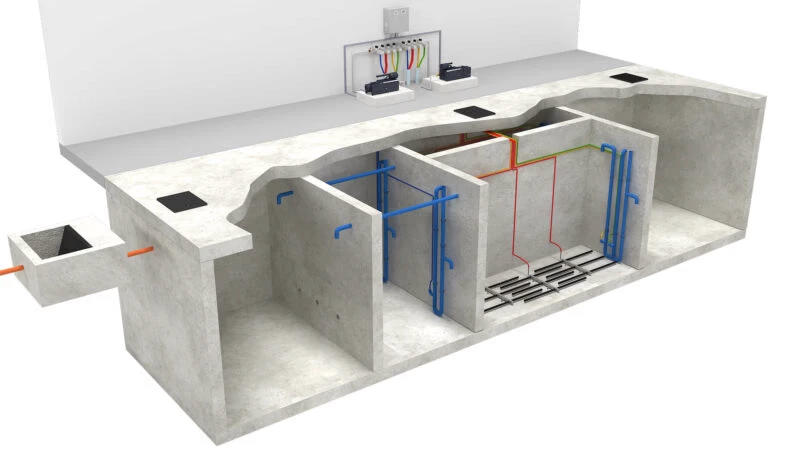

- Sewage & Wastewater Treatment Plant

- Decentralised Waste Water Treatment System

- Services

- Products

- Turnkey Projects

- Contact Us

- Lake Restoration

- FAQ